Checking blade alignment

While finishing the set up on my mitre guide, I decided it's time to check the alignment of the saw blade with the mitre track for parallel to each other, plus while doing this I had better check to see if the table saw fence was also parallel with the blade, calibrating the saw table top.

I tried using a micrometer I found this very fiddly to deal with although I did get readings of within 0.25mm, but the difference could have been me while fiddling. I needed something to be accurate with out any doubt at all, I didn't want to spend a fortune on other measuring equipment it had to simple, easy to set-up and cheap, so mulling things over and doing some web searching came up with this.

First simply Colour mark one tooth on the leading edge of the blade do this on both sides of the blade reason being Ill show you a little later on.

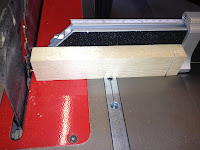

It's just an off cut of timber it can be any length you choose it to be, I have screwed into the end but off centre a small screw, as I wanted the measurement to be as near the table saw bed as possible, The screw head will be just touching the edge of the front tooth of the saw blade, now you can check you blade for alignment with the mitre guide by sliding it forwards to align with the back tooth on the saw blade while at the same time ROTATE the blade by hand aligning the marked tooth with the screw head when it's in position at the rear of the blade, if it just touching the tooth , yippee , then your blade is fine, if not then your saw blade is out of alignment.

I'm not going to try and explain how you go about re aligning you saw blades as I'm sure each manufacturer will possible recommend it's done differently as shown in there own manuals.

I found this method to be simply in expensive and much easier to use than fiddling with a micrometer, lucky for me my blade is spot on parallel to the mitre track.

Checking fence alignment

The preparation of your materials is very important, it's no good preparing stock which is not cut parallel , it just is as important to get this spot on as well as the mitre track being parallel and your mitre fence being also square to the blade.

I'm using the same jig and the same method of checking for alignment it's primarily a repeat of what you just read to check the alignment of the mitre gauge, only a slight difference I used a small steel square to keep the jig square to the fence as I checked it, seen here at the front of the blade using the same marked tooth, now repeat at back of blade.

Lucky for me I can adjust my fence as seen here with the four Allen screws/bolts, two either side of the fence , my fence was indeed out, not by an enormus amount but to much to be ignored.

To make adjustments slacken all four Allen screws, I simply used the jig to align the fence first at the back of the blade, by placing the screw head against the marked tooth then slid the fence to touch the other end of jig and mark a pencil line along the bottom edge of the fence onto the table saw bed then, I moved the jig to the front of the blade rotated the blade and moved the jig to the front of the blade placing the screw head against the marked tooth, I slid the fence up against the other end of the timber jig , keeping it touching the timber I then slowly move the far end of the fence to line up with the pencil line I had made earlier and then tightened all four Allen screws. I moved the fence in and out a few times and repeatedly checked it positions to double check for accuracy, all is fine. I removed the jig and left the fence in that position so I could cut some test pieces to double the test I had calibrated the saw correctly and no fine tuning would be needed.

I planed one edge of some old white melamine chipboard then rip cut it and then cross cut at exactly the same length as it's width to get a square. All four sides 210mm then as seen above marked the diagonals both measured 296mm, spot on.

Now that I'm satisfied the mitre guide is square with the blade and the table saw fence is aligned with the blade as well it now time to try a cut at 45 degrees, Simple set up the 45 angle and hey presto. enjoy. hc